Rohn Ck Pt Iditarod

Rohn Ck Pt Iditarod

Fairbanks

Fairbanks

Cessna 185-B Skywagon

N2550Z

SN#1850550

Rohn Ck Pt Iditarod

Rohn Ck Pt Iditarod

Fairbanks

Fairbanks

Tri-Star Aviation an FAR 135 1992 to 2014

N2550Z is no longer with us. Great memories rebuilding and flying around the US and Alaska

About Us - Iditarod -Iditarod Airforce - Atlas Air - Skywagon - On The Wing - Feedback - Josh&John

This page chronicles the restoration of an Alaskan work horse:

N2550Z Trade-a-Plane cover

photo Dec 2007

N2550Z Trade-a-Plane cover

photo Dec 2007

I'm a flying

project Paint me!

I'm a flying

project Paint me!

Wings off, time to go to work.

Wings off, time to go to work.

Going together, notice new windows

Going together, notice new windows

A work in progress Radios are installed

padded dash not in yet

A work in progress Radios are installed

padded dash not in yet

Interior primed DuPont DP50

Interior primed DuPont DP50

Flap

Flap

Wings and control surface

Burnt Orange/White

Wings and control surface

Burnt Orange/White

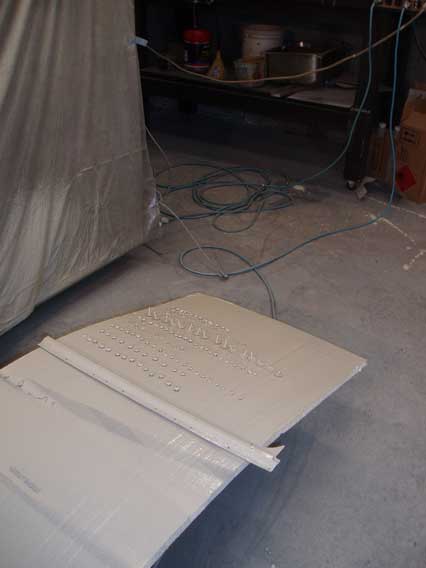

Painting screws and washers

Painting screws and washers

Going together

Going together

Finish N-Number shadow blocked

Finish N-Number shadow blocked Belly Pod installed

Belly Pod installed

Married to

EDO 2960 floats

Married to

EDO 2960 floats

The beginning

It's never Finished

The beginning

It's never FinishedI planned the restoration in 5 phases.

1. Outline; What will it look like and what modifications do we want. 2. Disassembly. 3. Stripping and Cleaning. 4. Repair and modifications. 5. Prep and Paint. 6. Assembly. 7. IO-520 upgrade. 8. EDO 2960 Floats, recondition.

Respirator HVLP

Geared Up

The Filter

Best taken in

stages, fuselage, wings then controls surfaces. Once again you gear up to

protect from chemical exposure. Alumi-Prep is applied then scrubbed with medium

Scotch-Brite to remove oxidized aluminum, dirt and oils. Clean with lots of

water to remove all cleaner. Alodine is then scrubbed on with Scotch-Brite. This

helps to inhibit corrosion propagation under paint. Rinse again with water. From

now till final painting I'm careful to handle parts only when wearing clean gloves.

Any oils from your hands will contaminate surface. I let dry overnight, tack-cloth then prime

with DP50.

I'm careful to

cover and keep cleaned primed wings, fuselage, controls, ect.

Paint: I used

DuPont Imron paint, it's extremely durable. 4775 White, 7455 Burnt Orange and

7502 Brown. We liked the combination of colors and the Orange we felt not only

looked good but was bright enough to help with visibility and collision

avoidance.

My weapon of

choice for shooting Imron is an HVLP. They deliver paint with warm high volume

air and produce very little overspray. It's a very easy system to master. Imron

is also a very toxic paint and my environment of choice is a full hood fresh air

respirator system. This brings fresh air from outside and is a must for any

painting. I hang a curtin of poly-sheeting around my painting area to keep all

overspray out of my shop area, using an exhaust fan at one end and a plywood

panel in the door opening at the other end with filters installed to reduce dust.

In stages, wings

first. I set up parts to be painted, mix paint, tack-cloth wipe, gear up in

tyvek suite, turn everything on and paint! I like to work the trap corners and

hard angles till covered.

Then I shoot a thin transparent coat in one direction,

a second thin coat in the other direction and after about 10 minutes a final

fill coat.

You can see when the paint fills, the texture is uniform and there is

a finish sheen. It's a find line and takes a practiced eye, if you cross it

you'll get sags and runs. Sags are bad, a whole layer of paint slides and I

don't have a good fix.

Runs can be fixed. I use a strip of masking tape, be

quick. While the paint is flowing apply tape and remove run, re-shoot a light

coat and hopefully you will have a seamless repair. I shot everything that was

being painted white first, including a cardboard box covered with all the

exterior screws and washers I would need.

Respirator HVLP

Geared Up

The Filter

Best taken in

stages, fuselage, wings then controls surfaces. Once again you gear up to

protect from chemical exposure. Alumi-Prep is applied then scrubbed with medium

Scotch-Brite to remove oxidized aluminum, dirt and oils. Clean with lots of

water to remove all cleaner. Alodine is then scrubbed on with Scotch-Brite. This

helps to inhibit corrosion propagation under paint. Rinse again with water. From

now till final painting I'm careful to handle parts only when wearing clean gloves.

Any oils from your hands will contaminate surface. I let dry overnight, tack-cloth then prime

with DP50.

I'm careful to

cover and keep cleaned primed wings, fuselage, controls, ect.

Paint: I used

DuPont Imron paint, it's extremely durable. 4775 White, 7455 Burnt Orange and

7502 Brown. We liked the combination of colors and the Orange we felt not only

looked good but was bright enough to help with visibility and collision

avoidance.

My weapon of

choice for shooting Imron is an HVLP. They deliver paint with warm high volume

air and produce very little overspray. It's a very easy system to master. Imron

is also a very toxic paint and my environment of choice is a full hood fresh air

respirator system. This brings fresh air from outside and is a must for any

painting. I hang a curtin of poly-sheeting around my painting area to keep all

overspray out of my shop area, using an exhaust fan at one end and a plywood

panel in the door opening at the other end with filters installed to reduce dust.

In stages, wings

first. I set up parts to be painted, mix paint, tack-cloth wipe, gear up in

tyvek suite, turn everything on and paint! I like to work the trap corners and

hard angles till covered.

Then I shoot a thin transparent coat in one direction,

a second thin coat in the other direction and after about 10 minutes a final

fill coat.

You can see when the paint fills, the texture is uniform and there is

a finish sheen. It's a find line and takes a practiced eye, if you cross it

you'll get sags and runs. Sags are bad, a whole layer of paint slides and I

don't have a good fix.

Runs can be fixed. I use a strip of masking tape, be

quick. While the paint is flowing apply tape and remove run, re-shoot a light

coat and hopefully you will have a seamless repair. I shot everything that was

being painted white first, including a cardboard box covered with all the

exterior screws and washers I would need.

The wings 1st coat

Finished Ailerons

Three color finished wing

Laying out the

color pattern with fine-line tape took a full day. We took a lot of time to get

it looking uniform and straight. After masking all areas not taking color from

getting overspray I shoot another coat of white on the areas taking color. This

is a really easy and fool proof way to seal the fine-line tape and it totally

prevents the other colors from bleeding in to the white. Shooting the color is

as easy as it gets. I pull the fine-line tape while the last coat is setting up.

You have to be really careful, it's easy to screw up the wet paint but if your

successful the line edges soften and I think it produces a better finished edge.

After 3 days, 2

1/2 gallons of primer 3 1/2 white, 2 orange and 2 quarts of brown it was

finished, my best paint project yet. No sag, two small runs and only two edge

bleeds and I "didn't" kick the paint pot over once.

N-numbers were

easy. We went with Mylar peal and stick, white with brown shadow block, a great

finish from Wes at Warning light of Alaska

6. Assembly:

One week before we were to depart for Oshkosh we hung the wings and began the

final assembly. Horizontal and vertical stab and all control surfaces mounted.

Assembled with all new AN hardware. Cables adjusted, rigged, tensioned and all fairings

installed. There are a lot of little thinks and attention to detail is

important, a missed wire or bad connection and something won't work right. This

is where tagging everything during dissemblely pays off. Fuel and electrical connected, no leaks upon fueling,

hooray! Kevin's

Upholstery from Merrill Field Airport installed the headliner. With the

skylights there were some tricky angles. Interior panels were an easy fit and

few odd and ends and interior complete.

Battery in,

fueled and successfully test flew on a Tuesday, no problems at all. Thursday

Diana and I loaded up our camping gear and headed across Canada and the Midwest

for Oshkosh and Air Venture trek 2005.

4.

Modifications (Alaska Sky Pod): The Belly Pod from Alaska SkyCrafters was

delayed for a few months but finely arrived. These pods are a jell-coat

fiberglass construction and form fitted to the contour of the Cessna 180/185

belly. Installation was very straight forward. The pod is mounted to the

aircraft belly using AN-Rivnuts and structural machine screws. It takes some

time centering the pod on the belly and marking the access holes for the fuel

and electric and making sure mounting hole location do not interfere with

aircraft ribs ect. After drilling all holes and ensuring a perfect fit, I

removed the Pod and painted Imron 4775 White, same used for and main aircraft

color. Thus it was mounted freshly painted and not dinged up from installation.

Hooking up the fuel couldn't have been easier. Some installations require

cutting the fuel supply line. The 185 however has a belly fuel drain with AN-T fitting,

this was simply replaced with a AN-Star fitting and the supplied line to the

SkyPod fuel tank was attached to this fitting. Fuel is transferred to the right

wing tank when it's capacity allows, with a DC pump. A 10amp CB was installed

and wired with an operating switch and pump On light on the dash. A gallon of

fuel in the pod and some adjustments and a check for leaks and the Fuel/Cargo

Pod was installed. This extra fuel has extended the endurance range to 8 hours

in some cases. It's long time without a Lav on board.

I'm very

impressed with the quality of these pods, ease of installation and the utility

they add. Other then painting it's an easy 8 hours. Alaska

SkyCrafters

offers two options, all cargo or Cargo/Fuel, (29 gallons).

7. IO-520

modification: It's great being on the home stretch of this restoration

project. During the year and a half Diana and I have been at this, the 185 has been

flyable all but 4 months and this is the last one. We choose the end of October,

there isn't much good flying till after the 1st of the year when lakes and

rivers are frozen solid and the days start getting longer.

Being around

180/185's all my aviation career and seeing the developments, epically the last

10 years, I knew the way we would go in upgrading our 185 from the IO-470 to the

Teledyne Continental Motors IO-520.

We choose the

Kenmore Air STC for mounting the Continental IO-520D and the P-Ponk STC for

hanging the McCauley 3 blade BlackMac prop and polished spinner. The engine will include

the Continental oil filter adapter, New AWI exhaust with seaplane muffler

extension, 6 point EGT/CHT engine analyzer, Quantity/flow fuel analyzer, Interav

Alternator conversion and Tanis preheat system.

There are many

options out there for engine vendors. I spent several months keeping an eye out

for IO-520 deals. It paid off, found a IO-520 from an aircraft mishap, ran out

of gas and engine was stopped on landing but it was short of the runway which

totaled the aircraft. Very low time engine with ECI cylinders.

The wings 1st coat

Finished Ailerons

Three color finished wing

Laying out the

color pattern with fine-line tape took a full day. We took a lot of time to get

it looking uniform and straight. After masking all areas not taking color from

getting overspray I shoot another coat of white on the areas taking color. This

is a really easy and fool proof way to seal the fine-line tape and it totally

prevents the other colors from bleeding in to the white. Shooting the color is

as easy as it gets. I pull the fine-line tape while the last coat is setting up.

You have to be really careful, it's easy to screw up the wet paint but if your

successful the line edges soften and I think it produces a better finished edge.

After 3 days, 2

1/2 gallons of primer 3 1/2 white, 2 orange and 2 quarts of brown it was

finished, my best paint project yet. No sag, two small runs and only two edge

bleeds and I "didn't" kick the paint pot over once.

N-numbers were

easy. We went with Mylar peal and stick, white with brown shadow block, a great

finish from Wes at Warning light of Alaska

6. Assembly:

One week before we were to depart for Oshkosh we hung the wings and began the

final assembly. Horizontal and vertical stab and all control surfaces mounted.

Assembled with all new AN hardware. Cables adjusted, rigged, tensioned and all fairings

installed. There are a lot of little thinks and attention to detail is

important, a missed wire or bad connection and something won't work right. This

is where tagging everything during dissemblely pays off. Fuel and electrical connected, no leaks upon fueling,

hooray! Kevin's

Upholstery from Merrill Field Airport installed the headliner. With the

skylights there were some tricky angles. Interior panels were an easy fit and

few odd and ends and interior complete.

Battery in,

fueled and successfully test flew on a Tuesday, no problems at all. Thursday

Diana and I loaded up our camping gear and headed across Canada and the Midwest

for Oshkosh and Air Venture trek 2005.

4.

Modifications (Alaska Sky Pod): The Belly Pod from Alaska SkyCrafters was

delayed for a few months but finely arrived. These pods are a jell-coat

fiberglass construction and form fitted to the contour of the Cessna 180/185

belly. Installation was very straight forward. The pod is mounted to the

aircraft belly using AN-Rivnuts and structural machine screws. It takes some

time centering the pod on the belly and marking the access holes for the fuel

and electric and making sure mounting hole location do not interfere with

aircraft ribs ect. After drilling all holes and ensuring a perfect fit, I

removed the Pod and painted Imron 4775 White, same used for and main aircraft

color. Thus it was mounted freshly painted and not dinged up from installation.

Hooking up the fuel couldn't have been easier. Some installations require

cutting the fuel supply line. The 185 however has a belly fuel drain with AN-T fitting,

this was simply replaced with a AN-Star fitting and the supplied line to the

SkyPod fuel tank was attached to this fitting. Fuel is transferred to the right

wing tank when it's capacity allows, with a DC pump. A 10amp CB was installed

and wired with an operating switch and pump On light on the dash. A gallon of

fuel in the pod and some adjustments and a check for leaks and the Fuel/Cargo

Pod was installed. This extra fuel has extended the endurance range to 8 hours

in some cases. It's long time without a Lav on board.

I'm very

impressed with the quality of these pods, ease of installation and the utility

they add. Other then painting it's an easy 8 hours. Alaska

SkyCrafters

offers two options, all cargo or Cargo/Fuel, (29 gallons).

7. IO-520

modification: It's great being on the home stretch of this restoration

project. During the year and a half Diana and I have been at this, the 185 has been

flyable all but 4 months and this is the last one. We choose the end of October,

there isn't much good flying till after the 1st of the year when lakes and

rivers are frozen solid and the days start getting longer.

Being around

180/185's all my aviation career and seeing the developments, epically the last

10 years, I knew the way we would go in upgrading our 185 from the IO-470 to the

Teledyne Continental Motors IO-520.

We choose the

Kenmore Air STC for mounting the Continental IO-520D and the P-Ponk STC for

hanging the McCauley 3 blade BlackMac prop and polished spinner. The engine will include

the Continental oil filter adapter, New AWI exhaust with seaplane muffler

extension, 6 point EGT/CHT engine analyzer, Quantity/flow fuel analyzer, Interav

Alternator conversion and Tanis preheat system.

There are many

options out there for engine vendors. I spent several months keeping an eye out

for IO-520 deals. It paid off, found a IO-520 from an aircraft mishap, ran out

of gas and engine was stopped on landing but it was short of the runway which

totaled the aircraft. Very low time engine with ECI cylinders.

On engine stand ready to go

Installation complete

First flight, new engine

Removed the old

IO-470 and prop. I'll sell these and recoup some of my cost. Removed throttle,

prop mixture and cowl flap cables and reinstalled new veneer controls. Firewall cleaned,

repainted

and silicone some minor holes. Set up wiring, new hoses and new AN hardware as

required.

Atlee Dodge Aircraft repaired, reconditioned and powder coated the old engine mount for use with the

IO-520. With the engine on a flange stand, installed the engine mounted with new

Lord mounts and built the engine exterior; Baffling, ignition, new AWI exhaust, EGT&

CHT probes, Reiff preheat, Gami injectors, fuel flow and the new electronics. It takes time and planning to

install, route and clamp wires and lines so as not to chaff or interfere and to

comply with the installation requirements. Even then they'll be some changes

after we hang the engine.

It took hours to

remove the IO-470 but it took 2 days to install and rig the IO-520.

8. EDO 2960

Floats: This last phase began in May

2006. Diana and I had planned a month to recondition the EDO floats we picked up

last winter. However they were in such bad shape, taking more time then I

expected, we didn't finish till August. Too late for this summers float season.

On engine stand ready to go

Installation complete

First flight, new engine

Removed the old

IO-470 and prop. I'll sell these and recoup some of my cost. Removed throttle,

prop mixture and cowl flap cables and reinstalled new veneer controls. Firewall cleaned,

repainted

and silicone some minor holes. Set up wiring, new hoses and new AN hardware as

required.

Atlee Dodge Aircraft repaired, reconditioned and powder coated the old engine mount for use with the

IO-520. With the engine on a flange stand, installed the engine mounted with new

Lord mounts and built the engine exterior; Baffling, ignition, new AWI exhaust, EGT&

CHT probes, Reiff preheat, Gami injectors, fuel flow and the new electronics. It takes time and planning to

install, route and clamp wires and lines so as not to chaff or interfere and to

comply with the installation requirements. Even then they'll be some changes

after we hang the engine.

It took hours to

remove the IO-470 but it took 2 days to install and rig the IO-520.

8. EDO 2960

Floats: This last phase began in May

2006. Diana and I had planned a month to recondition the EDO floats we picked up

last winter. However they were in such bad shape, taking more time then I

expected, we didn't finish till August. Too late for this summers float season.

EDO 2960 before

Ready to strip

Finished

Rigged and ready to float

EDO 2960 before

Ready to strip

Finished

Rigged and ready to float

My approach was the same as with the airframe, dissemble, strip, repair, reassemble and paint. With the EDO aluminum compartments and structure held together with steel hardware living for years in a marine environment, it was no easy task. Most bolts especially the main ones were corroded so bad penetrating oil was not enough to fee them, requiring drilling the bolt itself. Floats were then stripped and the compartments cleaned and pressure washed, removing years of silicone and whatever else was used to seal them. Repaired and replace old patches as needed. Sealing the cleaned compartments I use Randolph fuel tank sealer. I hang each float at it's balance point, pore in some sealer then use a reversed vacuum cleaner and rock the float coating the seams while air pressure forces the sealer into any gaps. works great. After the sealer dries I reapply the air pressure and use soapy water on the outside to check for any leaks. Sealing again as necessary This system works great for getting a good tight float. Re-assembling with new AN hardware I coat all the bolts with fuel lube. Fuel Lube is a pain to work with, sticky and hard to clean, only MEK removes it but it's impervious to fuel or water and it doesn't dry. Really helps with preventing future corrosion. After alidone it's prime with DP-50 and Imron white and a little trim paint, done.

This Cessna 185 has a factory float kit and had previously been on EDO floats so all the interior blocks were in place. May 2007 we married aircraft to floats. Hoisting, removing main gear, tail wheel and capping brake lines. Installing main gear float stubs and rear blocks then bolting the floats in place, attaching and tightening cross brace wires and rigging water rudder and retract cables. Floated May 28, 2007.

Dynon EFIS D10A: To say it's never done is an understatement. With the older flight instruments I decided to upgrade to one instruments has all. The Dynon EFIS D10A instrument has Pitot Attitude, Density Altitude, Pitot Airspeed, True Airspeed, Mag Heading, Vertical Speed, Turn & Bank, Slip indicator and OAT all in one unit and it fits in the standard 3 1/2 instrument hole. Installation is simple, I repositioned the Attitude indicator to an empty hole in the instrument panel and installed the Dynon in it's place. The Dynon has a Laser Ring Gyro and only requires 12 or 24VDC which I connected to a 2amp CB. I split the Pitot and Static lines, installed plastic compression T's and connected to the Dynon for Pitot-Static input. Additional accessories installed in the left outer wing were the temperature sensor and Mag Heading Sensor. Dynon uses Temperature in connection with Pitot-Static to resolve and display Density Altitude and True Airspeed. The Mag Heading Sensor stabilizes the heading indication to Magnetic.

The Dynon unit is not TSO or STC approved and requires a FAA Form 337 for field approval by the FAA. The FAA also has engineering guidelines for the installation of EFIS units (Electronic Flight Instrument Systems) The FAA requires all required Flight Instruments not be removed from the aircraft and placard "VFR ONLY". I have found the Dynon very accurate and a great tool. When you consider the errors these older flight instruments develop and the cost for overhaul or new instruments the Dynon is an economical option.

If your installing an EFIS system in your aircraft here are links to the documents the FAA requires. EFIS Installation guidelines, Flight Manual Supplement and FAA form 337 back page language. Format is MS Word.

The Logbooks: Regardless of an Oil Change, Annual Inspection or Restoration the FAA requires a record of all work preformed and return to service release. STC's, FAA form 337's and LogBook entries: Here is a comprehensive list of the STC and field approvals I used. Most of the modifications were installed under FAA Supplemental Type Data Certificate, commonly known as STC. These are issued from FAA engineering to the manufacturing vendor after meeting stringent design, engineering and testing requirements. Each STC has it's own set of instructions or procedures. Sometimes various options are available to comply with these instructions. FAA Advisory Circular 43.13 has additional guidelines and practices which must also be consulted and complied with. Modifications not covered under an STC were installed under a Field Approval by the FAA, a onetime installation verified and approved by a local FAA maintenance inspector. Cee Baileys Windshield CEE Baileys STC SA5451NM Alaska SkyPod, Alaska SkyCrafters STC

SA02179AK

Alaska SkyPod, Alaska SkyCrafters STC

SA02179AK

FP-5, Electronics International STC SA00068SE

UBG-16, Electronics International STC SA0068SE

FP-5, Electronics International STC SA00068SE

UBG-16, Electronics International STC SA0068SE

Folding removable Jump Seats SA 02008 AK

Folding removable Jump Seats SA 02008 AK

InterAV Alternator Conversion, Interav STC

SA334SW

MLJ Extended Baggage, Field Approval FAA form 337

MLJ Firewall mounted battery, Field Approval FAA

form 337

Reiff Turbo Preheat Systems

Snyder Wheel Skis, Dick Snyder STC

AirStreak Tundra Tires, AirStreak STC

True Lock Axle Locks SA00780SE

Cabin Skylights, Cessna OEM installation FAA form

337

**Home**

InterAV Alternator Conversion, Interav STC

SA334SW

MLJ Extended Baggage, Field Approval FAA form 337

MLJ Firewall mounted battery, Field Approval FAA

form 337

Reiff Turbo Preheat Systems

Snyder Wheel Skis, Dick Snyder STC

AirStreak Tundra Tires, AirStreak STC

True Lock Axle Locks SA00780SE

Cabin Skylights, Cessna OEM installation FAA form

337

**Home**